RD Aluminium is commited to provide high quality aluminium extruded products and superior customer service with a focus

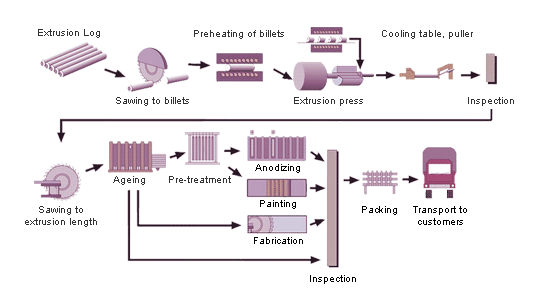

on value-added products to ensure customer satisfaction. The total operation can be viewed below

- The starting material for making aluminium extrusions is

the aluminium log or billet. The next process is to cut the long

extrusion log into suitable lengths for extrusion based on press

capacity and the final extruded length.

Extrusion involves pressing a preheated aluminium billet

(450-500°C) under high pressure through a die the opening of

which corresponds to the cross-section of the extrusion.

- The pre-heated billet is loaded into the container and squeezed

through the die opening. Typical press sizes range from 1,600

tonnes to 6,500 tonnes, which is sufficient force to cause the

aluminium to flow plastically and exit the die at extrusion speeds

in the range of 5-80 m/min.

At the exit of the die the temperature of the extrusion will be in

excess of 500 deg. C. The extruded length may be as long as

50 metres and may consist of one strand or multiple strands of

the same section.

With most commercial alloys the extrusion will be cooled or

quenched as it exits the press.

- RD plants have in-house capabilities in fabrication such as re-cut,

machining, and finishing, (e.g. anodising, powder coating).

We emphasizes the highest standards in quality for both

products and services to meet customer expectation. This has

been achieved through the adoption of quality principles and by

ensuring that all employees understand the importance of quality

performance. All operations of RD Aluminium have accreditation

under ISO 9000 quality system.